Electrostatics

The electrostatic part of KosekGroup focuses on problems associated with solid particle agglomeration and wall-sheeting in gaseous environments. Recently our research involves electrostatic charging of plastics and their subsequent separation that aims to improve plastic waste treatment. Additionally, we study parameters affecting the process of electrospraying and nanoparticle deposition.

The production, transportation and storage of insulator powders are all associated with the accumulation of excess electrostatic charge. Particles of industrially important powders like polymers, flour, medicaments or pigments collide with other particles as well as with a device walls during their production and transportation. Each collision leads to the generation of excess electrostatic charge on particle surfaces by the means of triboelectrification, i.e., charging by friction that may result in particle agglomeration or the formation of particle wall sheets.

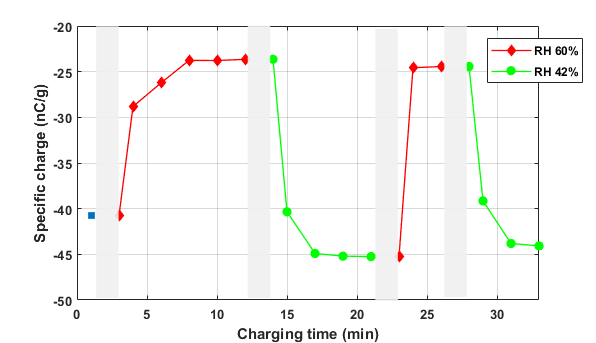

Particle-wall charging

Using two self-constructed apparatuses (cascade method apparatus and shaking apparatus) we measured the charging dynamics of polyethylene (PE) particles in contact with a metal wall under various conditions [1]. We showed that both the speed of charging and the saturation charge decrease with air humidity and how rapid humidity drops affect the charging. The increase in collision force acting between particles and wall leads to bigger saturation charge values, because additional area on the surface of rough PE particles that would be otherwise unreachable for charging can get into contact with the wall. The combination of experimental results with our unique model based on discrete element method (DEM) paired with condenser model for the description of particle-wall charging showed that experimentally observed faster charging of PE particles at elevated temperatures can be explained by the softening of PE particles.

Particle-particle charging

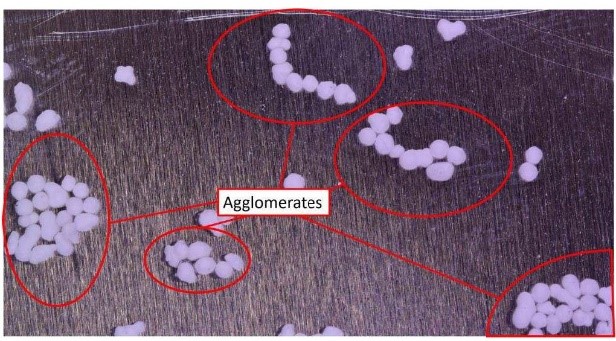

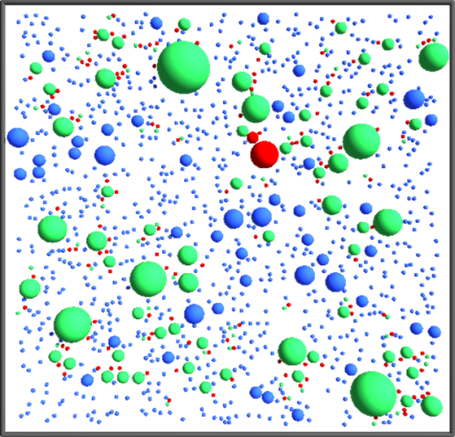

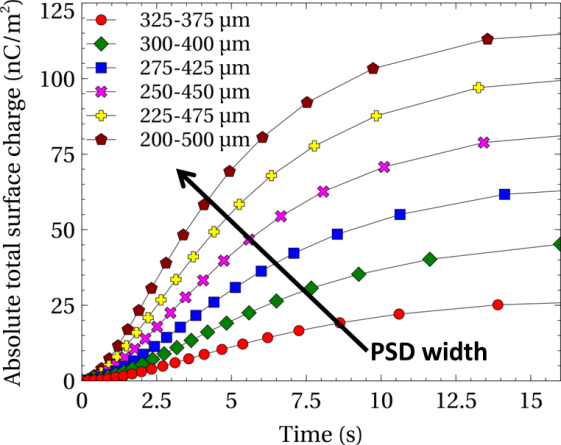

Mathematical modeling: Using self-developed DEM model considering the balance of transferrable charged species (electrons or ions) we predicted the particle-particle charging dynamics for polyethylene particles [2]. We specifically showed that particulate systems of broad particle size distributions produce significantly charged particles. The particles carried bipolar charge with respect to particle size. Moreover, our results indicated that if a particulate system reaches critical charge value, the orbiting motion of particles of opposite polarities begins to occur and is further followed by electrostatically-induced particle agglomeration.

Experimental investigations: Experiments involved the charging of powder PE samples in self-designed shaking apparatus and subsequent separation of the charged sample in electrostatic separator. Results show that particle-particle charging indeed leads to bipolar charging, whereas particle-wall charging produces charged particles of one polarity only. Therefore, particle-particle charging can typically lead to agglomeration of particles, while particle-wall charging is associated with the risk of fouling. The existence of electrostatically-induced particle agglomerates has been also demonstrated.

Particle collision mechanics - the problem of restitution coefficient

The agglomeration and fouling of particles in industrial systems is affected not only by electrostatic charge, but also by collisions of particles that dissipate a fraction of particle kinetic energy. The less kinetic energy a particle has, the bigger is the probability of formation of agglomerate or a wall-sheet. The restitution coefficient is a measure of energy dissipation during collision of particles. It is often used as a parameter in mechanistic models; however, due to the lack of understanding of this parameter, its value is typically arbitrary. To make the description of particle mechanics more precise, we not only measured the restitution coefficients of PE particles, but also developed an unique DEM model that enabled us to predict the restitution coefficient of PE particles of various shapes. Thus, we suggest what shapes of primary particles or even particle agglomerates are more prone to attach to a metal wall due to a significant loss of kinetic energy by collisions.

Electrostatic separation of plastic waste

Another promising area of research regards the separation of plastic particles. Using self-designed rotary tribocharger, we utilize the fact that saturation charge is material-dependent and therefore we charge particles of various industrially important plastic materials (PET, PP, PVC), each to a different saturation charge. After that, the plastics are separated in electrostatic separator. Our objective is to identify conditions suitable for the utilization of triboelectric and corona charging for the purposes of plastic waste separation in electric field.

Electrospraying

Although we deal typically with 1 mm particles of plastics in our laboratory, electrospraying is a method that can produce much smaller particles of various materials – from tens of nanometers to micrometers. Although the particle size distribution of sprayed particles is seemingly controlled only by electric field and is therefore expected to be uniform in stable electric field, in reality several other parameters affect not only the size of sprayed particles, but also the uniformity of the deposited layer. Our current focus is to ensure that uniform layers of particles are sprayed and that we can control the radius of formed nanoparticles by electrospraying parameters like solvent conductivity, viscosity, surface potential and electric field developed in the spraying cell. We attempt to optimize the process of electrospraying that has significant potential for improvement in several industrial areas, for example, in car painting, where about 30% of colorant is currently wasted.

By the means of DEM modeling we closely investigate the mechanism of particle attainment in electric field during electrospraying and discuss the parameters that lead to the formation of layers of various particle densities. Moreover we identify typical patterns of particle arrangement in such layers.

References:

[1] Jantač, S., Konopka, L. and J. Kosek. Experimental study of triboelectric charging of polyethylene powders: effect of humidity, impact force and temperature. Journal of Electrostatics (Submitted)

[2] Konopka, L. and J. Kosek, Discrete element modeling of electrostatic charging of polyethylene powder particles. Journal of Electrostatics, 2017. 87: p. 150-157