Computational Science

KosekGroup has a state-of-art expertise in models for:

- Colloid dispersions.

- Morphology evolution.

- Structure-property in complex materials.

- On-line process optimization and control.

- Electrostatic charging.

Models were developed for a broad class of problems:

- Polyolefin particles and thermodynamics.

- Polyurethane and polystyrene foams.

- Emulsion copolymerization.

- Polymerization reaction engineering.

- Electrochemical systems.

- Nano-particle layer deposition.

Historically our modelling section developed as a theoretical counterpart to the experimental laboratory of polymer reaction engineering, but nowadays we have a lot to offer to our collaborators both from industry and from academia in the fields of engineering and natural sciences in general.

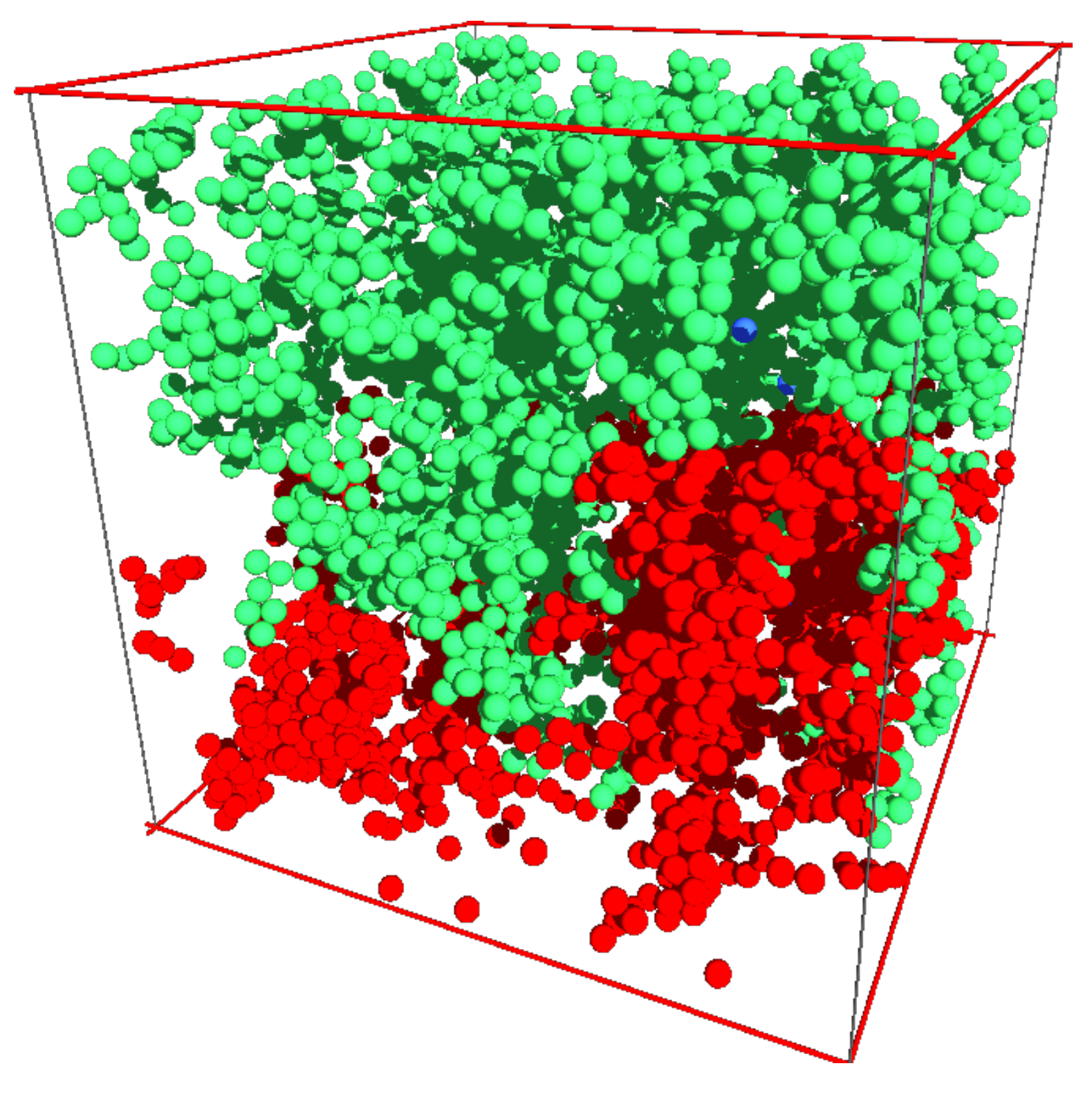

We developed unique mathematical models of particulate colloid dispersions applicable for the description of complex fluids present in our everyday life like paints, adhesives, coatings, food products and cosmetics. The models are based on the first principles Discrete Element Method (DEM) [1] and represent state-of-the-art in the prediction of rheological behavior [2] and understanding of mechanisms underlying undesirable phenomena such as coagulum formation and fouling that are of extreme importance for producers of synthetic latexes [3] [4].

We developed unique mathematical models of particulate colloid dispersions applicable for the description of complex fluids present in our everyday life like paints, adhesives, coatings, food products and cosmetics. The models are based on the first principles Discrete Element Method (DEM) [1] and represent state-of-the-art in the prediction of rheological behavior [2] and understanding of mechanisms underlying undesirable phenomena such as coagulum formation and fouling that are of extreme importance for producers of synthetic latexes [3] [4].

Big area of our interested has always been investigation of structure-property relationships and morphology evolution in high performance materials. Spatially 2D/3D structure of heterogeneous material is obtained either as an output of mathematical models [5] [6] [7] or by experimental characterization (e.g. using X-ray micro-tomography) [8] [9] and used for prediction of material application properties. Typical areas of our expertise include, for instance, heat insulation properties of polymeric foams [10] [11] [12], evolution of morphology in hetero-phase polymers [6] [13], or transport-reaction characteristics and morphogenesis of porous polyolefin powders [7] [9] [14].

Big area of our interested has always been investigation of structure-property relationships and morphology evolution in high performance materials. Spatially 2D/3D structure of heterogeneous material is obtained either as an output of mathematical models [5] [6] [7] or by experimental characterization (e.g. using X-ray micro-tomography) [8] [9] and used for prediction of material application properties. Typical areas of our expertise include, for instance, heat insulation properties of polymeric foams [10] [11] [12], evolution of morphology in hetero-phase polymers [6] [13], or transport-reaction characteristics and morphogenesis of porous polyolefin powders [7] [9] [14].

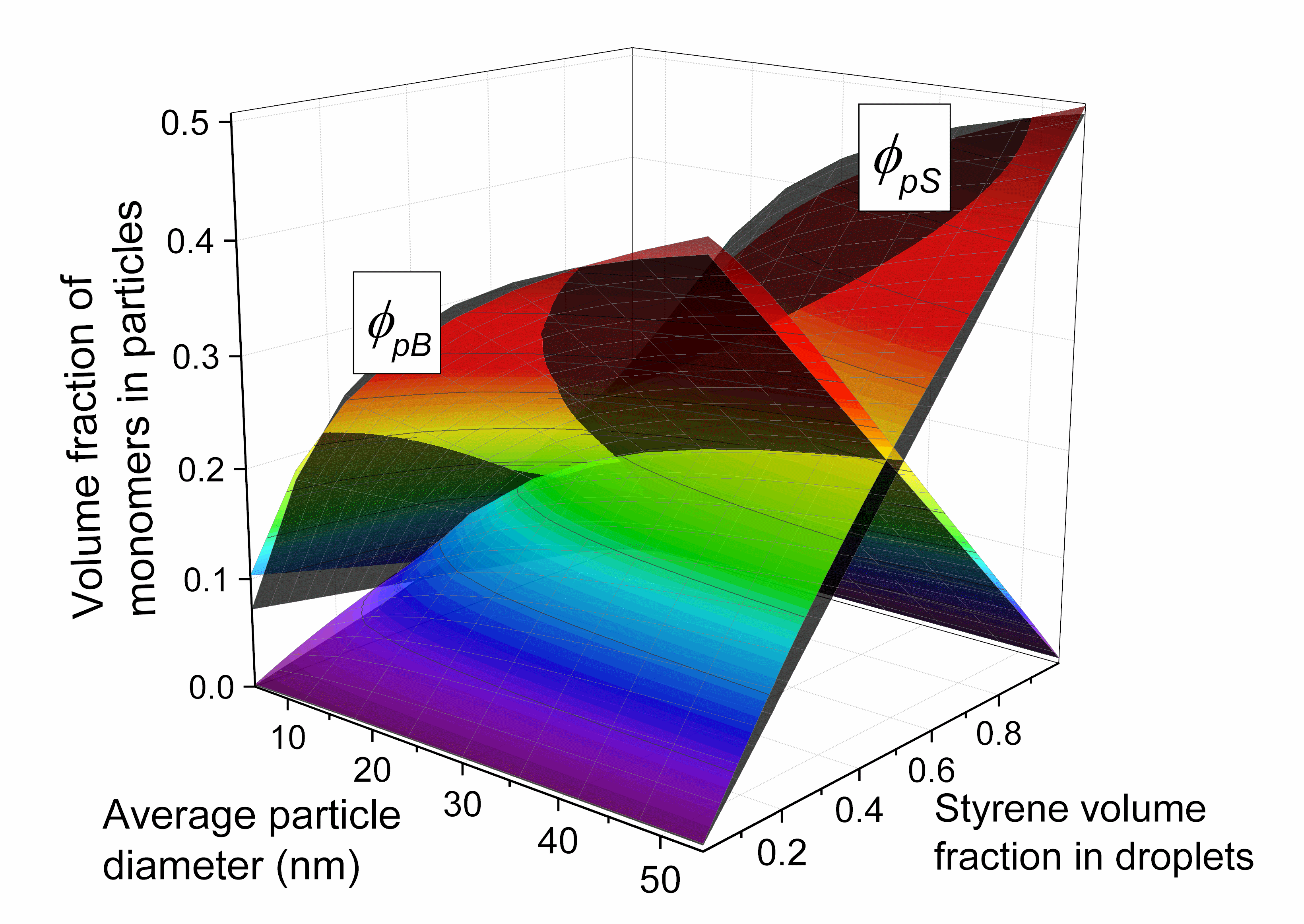

Thanks to our long-term cooperation with industrial partners we are always ready to develop fast, robust and reliable models suitable for process optimization and control, which was demonstrated in real time control and optimization of BASF pilot plant semi-batch emulsion copolymerization reactor involving 4 co-monomers [15] [16], intensification of continuous production of styrene-butadiene rubber (SBR) in Synthos Kralupy [17], or modelling of polymerization in smart-scale tubular reactors [18].

Thanks to our long-term cooperation with industrial partners we are always ready to develop fast, robust and reliable models suitable for process optimization and control, which was demonstrated in real time control and optimization of BASF pilot plant semi-batch emulsion copolymerization reactor involving 4 co-monomers [15] [16], intensification of continuous production of styrene-butadiene rubber (SBR) in Synthos Kralupy [17], or modelling of polymerization in smart-scale tubular reactors [18].

References:

[1] Kroupa M., Vonka M., Kosek J.: Modeling the Mechanism of Coagulum Formation in Dispersions, Langmuir, 2014, 30 (10): 2693–2702.

[2] Kroupa M., Vonka M., Soos M., Kosek J.: Utilizing the discrete element method for the modeling of viscosity in concentrated suspensions, Langmuir, 2016, 32 (33): 8451-8460.

[3] Kroupa, M.; Vonka, M.; Soos, M.; Kosek, J. Size and Structure of Clusters Formed by Shear Induced Coagulation: Modeling by Discrete Element Method. Langmuir 2015, 31: 7727–7737.

[4] Kroupa M., Vonka M., Soos M., Kosek J. (2017) Probing Coagulation and Fouling in Colloidal Dispersions with Viscosity Measurements: In Silico Proof of Concept. In: Advances in Polymer Science. Springer, Berlin, Heidelberg

[5] Vonka M., Nistor A., Rygl A., Toulec M., Kosek J.: Morphology model for polymer foams formed by thermally induced phase separation, Chemical Engineering Journal, 2016, 284: 357-371.

[6] Vonka M., Kosek J. Modelling the morphology evolution of polymer materials undergoing phase separation. Chemical Engineering Journal, 2012, 207-208: 895-905.

[7] Grof Z., Kosek J., Marek M.: Modeling of morphogenesis of growing polyolefin particles. AICHE Journal, 2005, 51 (7), 2048 – 2067.

[8] Nistor A., Toulec M., Zubov A., Kosek J.: Tomographic reconstruction and morphological analysis of rigid polyurethane foams, Macromolecular Symposia, 2016, 360 (1): 87-95.

[9] Šeda L., Zubov A., Bobák M., Kosek J., Kantzas A. Transport and Reaction Characteristics of Reconstructed Polyolefin Particles. Macromolecular Reaction Engineering, 2008, 2 (6): 495–512.

[10] Ferkl, P.; Toulec, M.; Laurini, E.;Pricl, S.; Fermeglia, M.; Auffarth, S.; Eling, B.; Settels, V. & Kosek, J. Multi-scale modelling of heat transfer in polyurethane foams, Chemical Engineering Science, 2017, 172, 323 - 334

[11] Ferkl P., Karimi M., Marchisio D. L., Kosek J.: Multi-scale modelling of expanding polyurethane foams: Coupling macro- and bubble-scales, Chemical Engineering Science, 2016, 148, 55–64.

[12] Ferkl P., Pokorný R., Kosek J.: Multiphase approach to coupled conduction–radiation heat transfer in reconstructed polymeric foams, International Journal of Thermal Sciences, 2014, 83: 68–79.

[13] Vonka M., Šeda L., Kosek J. Modelling of the High-Impact Polystyrene Morphogenesis. Macromolecular Symposia, 2011, 302: 151–160.

[14] Zubov A., Pecháčková L., Šeda L., Bobák M., Kosek J. Transport and reaction in reconstructed porous particles: Model validation. Chemical Engineering Science, 2010, 65(7): 2361–2372.

[15] Zubov, A.; Naeem, O.; Hauger, S. O.; Bouaswaig, A.; Gjertsen, F.; Singstad, P.; Hungenberg, K.-D. & Kosek, J. Bringing the On-Line Control and Optimization of Semibatch Emulsion Copolymerization to the Pilot Plant, Macromolecular Reaction Engineering, 2017, 11, 1700014

[16] Chaloupka, T.; Zubov, A. & Kosek, J. Espuña, A.; Graells, M. & Puigjaner, L. (Eds.) Real-time Hybrid Monte Carlo Method for Modelling of 4 Monomer Semi-Batch Emulsion Copolymerization, 27th European Symposium on Computer Aided Process Engineering, Elsevier, 2017, 40, 259 - 264

[17] Zubov, A., Pokorny, J., Kosek, J. Styrene-butadiene rubber (SBR) production by emulsion polymerization: Dynamic modeling and intensification of the process. Chemical Engineering Journal, 2012, 207-208: 414-420.

[18] Pokorný R., Zubov A., Matuška P., Lueth F., Pauer W., Moritz H.-U., Kosek J.: Process model for styrene and n-butyl acrylate emulsion copolymerization in smart-scale tubular reactor, Industrial & Engineering Chemistry Research, 2016, 55 (2): 472-484.